Reliable and Customized Screw Compressors

Screw Compressor Manufacturers

Daily production of over 300 units. We maintain mature production setups, including fully automated sheet metal and spraying lines equipped with robotic arms.

Rotary Screw Air Compressors

Power Range

7.5 kW ~ 355 kW

(10 HP ~ 475 HP)

(10 HP ~ 475 HP)

Air Capacity

0.72 m³/min ~ 61 m³/min

(25 CFM ~ 2150 CFM)

Working Pressure

5 bar ~ 24 bar

(70 psi ~ 350 psi)

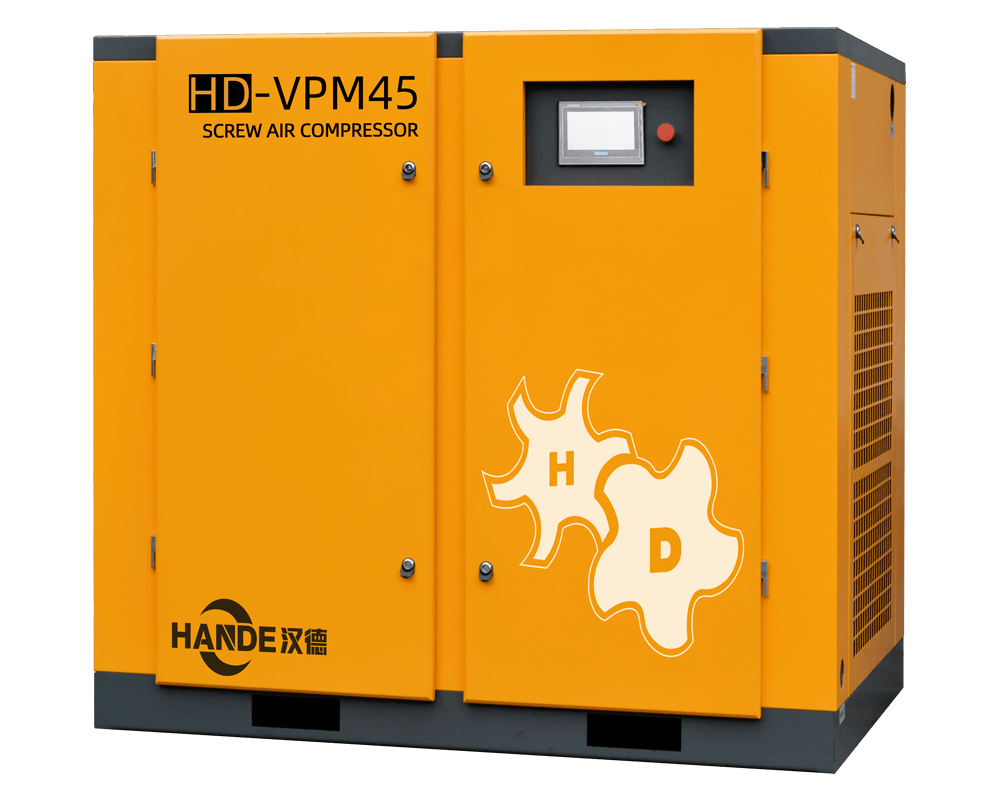

Variable Speed Screw Compressors

Saving up to 38% in energy costs, and ensures consistent performance with low noise and reliable air cooling, making it ideal for various industrial applications.

Fixed Speed Air Compressors

Provides reliable, consistent air compression with up to 5% energy savings. Features a customizable design, intelligent control, and easy maintenance, suitable for various industrial applications.

Two Stage Screw Compressors

Delivers up to 15% energy savings with reliable, steady air compression, and low maintenance, ideal for demanding industrial applications.

Tank Mounted Screw Air Compressors

Combines an air tank, screw compressor, air filter, and dryer in one compact unit, saving up to 60% floor space. Ideal for space-constrained workshops needing reliable, continuous air supply.

300 Unit Compressors per Day

Our factory have fully automatic sheet metal cutting, processing, and spraying production lines for mass production.

Custom Screw Compressor Service

Our OEM services combine your unique designs with our manufacturing prowess to create air compression solutions that are truly your own.

Solutions for Industry Needs

Low-pressure air for Cement, Two-stage compression air for Textile, Integrated systems with high pressure for laser cutting.

Manufacturing Process

Our factory maintains a fully integrated manufacturing process, covering every stage of screw compressor production from start to finish within our premises. This allows for consistent quality control and efficiency in production.

Laser Cutting

We use laser cutting equipment to precisely shape the metal components required for our compressors. This ensures exact dimensions and high precision.

Metal Bending

We have bending machines at our production site to provide stable and precise structures for different types of air compressors.

Spray Line

We added a spray coating line to achieve a durable surface finish that ensures longevity and resistance to environmental factors. We also increased the daily output of our factory.

Assembly Line

On our assembly line, experienced technicians assemble each unit with care, testing components at every stage to ensure optimal function and reliability. This final step includes all necessary checks to meet industry standards.

Consult Your Compressed Air Solution Experts

We know your time is valuable, so we help customers provide air compressors that meet your requirements, quality and value, on time and within budget.